Welcome to Part II of our three-part series discussing how we at KSS approach the Construction Administration process, elaborating on our previous post where we discussed the importance of assembling the right people to shepherd the work in the office as well as in the field. As with anything, building the appropriate team around a project is only one aspect in helping to set it up for success. Through our experience working on a wide range of building types using all methods of construction delivery, we have been able to refine how we approach each project and capitalize on what each team member brings to the table. This starts with establishing and maintaining a positive relationship with everyone from the Client to those fabricating individual elements of the project. With enough at stake in what we do on a day-to-day basis, contentious posturing and negative interactions furthering misconceptions of the Architect-Contractor relationship have no place in our industry. As was mentioned in our previous post, this should be the fun part of the job!

UNDERSTANDING THE PROCESS

Despite our best intentions, there is not always a firm understanding of the above-mentioned philosophy the day shovels break ground on every project. With this in mind, one of our first tasks onsite is to clearly describe our approach to Construction Administration and work collaboratively with the team to establish a process by which we all operate throughout the duration of the project. By setting expectations for RFI and Submittal response timelines, site visit frequency, and payment application processing, among many other things, we can set expectations for how we all operate. This can even go as far as learning how best to communicate certain things in the field to others. With team members coming together with a wide range of experiences and spanning several generational gaps, there is no one-size-fits-all solution, so taking a more personal approach is the only way to keep everyone on the same page.

TEAM ENGAGEMENT

To incentivize the team to bring their full attention to the project, we have found it worthwhile to involve everyone in the conversation regarding the aspirations of the client and the design team. Being able to engage with key players onsite and get them excited about the design and high level of quality anticipated for the project gives them ownership in the work. Involving tradespeople throughout the process provides many opportunities for them to advise on potential improvements to the execution of details and other intricate assemblies. To reference big design moves, we use the analogy of “the big blue wall” when talking about our efforts, walking the site with the trades, and pointing out critical design moves. The more people who understand the importance of the design intent (aka “the big blue wall”) the more likely further consideration will be placed on its construction and enable those in the field to make informed decisions impacting it with minimal design assistance. It’s honestly amazing to watch sub-contractors engage each other to coordinate their installations to honor the design intent and celebrate their contributions to the effort. Everyone wants to walk away from the project having left something they can be proud of.

SETTING EXPECTATIONS

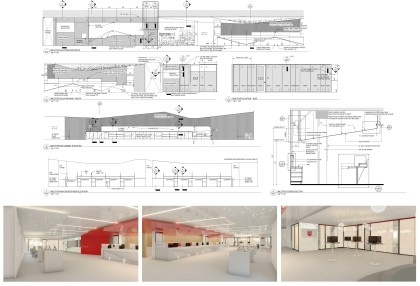

Most of us in the design and construction industry are visual people. While this is readily apparent in how we transcribe the intent of our work utilizing two-dimensional construction drawings, there are many things that simply cannot be conveyed as well as they can be without the use of additional tools. One method we have been utilizing to help in this process is the incorporation of three-dimensional renderings into our contract documents for reference by the project team. These resources are already being prepared by the team to assist throughout the design phases of the project, so why not incorporate them into the drawings for all to use as a reference? From project estimators to painting sub-contractors, these visual aids provide a readily accessible shortcut to understand the vision for the primary interior and exterior design moves throughout a project. Now with more and more people relying upon electronic means to access drawings in lieu of printed sets, the use of color is no longer taboo and can really help improve the product we hand over to those in the field.

Renderings added to documents for Rutgers One Stop garnered buy-in to the design ideas from those in the field.

Renderings added to documents for Rutgers One Stop garnered buy-in to the design ideas from those in the field.

Bringing things further into reality, project mock-ups are another invaluable tool which are generally under-utilized within our industry. Most are only partially completed, do not represent a full complement of exterior components, and are not completed in time to have an appreciable influence on the project. These are great tools that allow the trades to understand how best to construct elements of the building, locate scope gaps, understand potential assembly performance issues, fine-tune sequencing as well as assist the design team and owner make critical exterior finish decisions. Why wait until you’re up against the clock to hash out the details? Ensure this is included within the project contract and buy-outs, add it as a milestone to the construction schedule, and make it a priority for the project.

A precast mock-up for 2505 Bruckner Avenue.

A precast mock-up for 2505 Bruckner Avenue.

COLLABORATION IN THE FIELD

At the end of the day, we as Architects and Engineers are not the ones in the field physically building our projects from the ground up. As such, we are reliant upon our partners in the construction industry to help execute our vision. The more we on the design side can integrate ourselves with those onsite, the more both sides can become better informed and develop ourselves for this project as well as others down the road. While both sides bring different things to the table, there is nothing wrong with facilitating refinement along the way based upon knowledge and past experiences regarding performance, constructability, code compliance and aesthetics. Make yourself available on job sites, get to know the individuals there, and establish those relationships. RFIs become less of a burden when you’re solely documenting something you’ve already resolved in the field, instead of being surprised and wasting time trying to decipher the request.

Don’t be afraid to ask questions to better understand why things are installed the way that they are or why certain typical details are what they are. Bring manufacturers onsite to review the installations of their materials in the field. Get a second opinion and have an open mind to alternative products and methods. The more we collaborate the more we bring to the table, which can be invaluable here in an industry that is ever-evolving.

We will wrap up this CA Blog Series with Part III in which we will share how these proactive measures in the field enable us to improve the quality of our work under construction, as well as better inform our design and documentation processes for future work.